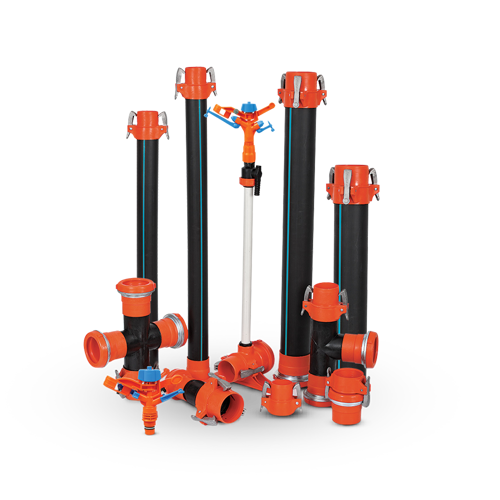

Sprinkler Irrigation Pipe Production Line

- Product Code: Yağmurlama Borusu Üretim Hattı

- Categories: APPLICATIONS

- E-Mail Sales: sales@ztechmakine.com

- Whatsapp: Click to start conversation

Sprinkler Irrigation Pipe Production Line

Ztech Makine, which has many years of experience and expert staff on pipe production machines and polymers, offers a turnkey, professional production line for the production of polyethylene sprinkler pipes .

We can offer economical and high performance serial model options according to criteria such as investment capital and production capacity expectations.

The production line is designed according to your desired pipe diameter and pressure class options.

Single layer and ABA 3 layer pipe production line options are offered according to customer request.

For example, the equipment of a line that produces PE Sprinkler Pipes in the diameter range of Ø50-160 mm is as follows:.

- Raw Material Loader and Dryer

Extrusion production system is a continuous production method. In order for the production line to operate without stopping, the extruder must be constantly fed with raw materials. Thanks to the automatic loading system, when the material in the bunker runs out; The loader detects this through the sensor and ensures that the granulated raw material is filled from the bag into the bunker.

Plastic raw materials can absorb moisture during transportation or waiting in stock. Thanks to the drying feature of the bunker, the moisture in the granules is removed.

You can read about the effects of moisture on plastic pipes in the technical information category.

2. Single Screw Extruder

Ztech Single Screw Extruders offer many options depending on your capacity needs and machine features.

- Touch control panel,

- Fault detection and repair with remote access,

- Ability to work synchronously with other machines on the line,

- Ability to produce uninterruptedly for very long periods thanks to the in-panel air conditioning cooling system,

- Specially designed barrier, high speed screws provide the advantage of low energy consumption, high capacity, homogeneous mixing and processing.

- Thanks to Helical Grooved Feed, it provides balanced raw material intake to the screw even at high capacity.

- Automatic self-protection against high torque, pressure and temperature alarms,

- Warning the operator with a light warning in case of alarm

3. Line Extruder

Ztech Co-ex Extruders are used for line application on pipes. Color of the line on the pipe; It is used to inform the consumer about the intended use of the pipe. These colors vary depending on the standard adhered to. değişmektedir.

4.Melt Filter

Ztech Melt Filters ensure the retention of impurities when using recycled granular material. In this way, blockages that may occur in the die head are prevented and problems such as pipe puncture, rupture and explosion are prevented.

5.Die Head

Ztech Die Heads, the molecular structure of the raw material; It has a design that allows the pipe to achieve an alignment that will increase the pressure, elongation, tensile and yield strength values.

The die head is preferred according to single-layer and ABA 3-layer pipe production options.

Pipes with different diameters and PN values are produced by making pin and spinneret molds according to the desired pipe pressure class and raw material MRS values.

5.Calibration Sleeve

Ztech Pipe Calibers are used to cool the hot material coming out of the die head under vacuum to produce the desired outer diameter tolerance.

6.Vacuum and Cooling Tanks

Ztech Vacuum and Cooling Tanks cool the pipe with vacuum and cold water so that the outer diameter of the pipe can be calibrated at the desired value.

Models are offered according to the capacity of the production line and the pipe diameter range options to be produced.

It is made of stainless material to protect against rust and corrosion..

7.Haul-Offs

Ztech Haul-Offs are used to produce the pipe in the desired wall thickness and speed. Ztech tractors, which can work completely synchronously with the extruder , respond immediately to changes in extruder speed.

Thanks to its servo-driven motors, it provides a stable pulling speed from the lowest speed to the highest speed.

8.Cutter

Ztech Pipe Cutters are used to automatically cut the pipe to the desired length.

ZTT160 cutter was designed especially for cutting PE pipes without burrs and ovalization . The pipes coming out of the ZTT model cutter give excellent results in the cap bonding process.

9.Tilting Table

It is used to stack the pipe by tilting it to the right or left after cutting.

10.Sprinkler Head Friction Welding Machine

Ztech Sprinkler Head Friction Welding Machines are used to bond male and female heads to the pipe by friction welding method.

Option Offers:

1. Sprinkler Head and Other Attachment Molds

For our customers who want to produce or have sprinkler pipe fittings produced in addition to pipe production ; We offer Ztech injection molds .

2. For rubbing the pins of Ø50-Ø160mm Latched Sprinkler Pipe Heads and Abots; You can examine our Rivet Fastening Machine .